Facilities Management in the UK: How to Handle Maintenance, Compliance, and Cost Control

24 Jan, 2026Keeping a building running smoothly in the UK isn’t just about fixing broken lights or cleaning bathrooms. It’s a complex system of maintenance schedules, legal rules, and tight budgets that can make or break a business. If you’re managing offices, hospitals, schools, or warehouses, you’re not just a custodian-you’re a critical part of the organization’s bottom line. And if you’re not getting all three right-maintenance, compliance, and cost control-you’re leaving money on the table and risking fines, shutdowns, or worse.

Why Facilities Management Matters More Than Ever in the UK

In 2025, the UK facilities management market was worth over £100 billion. That’s not a typo. It’s bigger than the country’s entire airline industry. But here’s the catch: 62% of UK businesses say their FM budgets haven’t kept up with rising energy, labor, and materials costs, according to the British Facilities Management Association. That means you’re doing more with less-and doing it under more scrutiny than ever.

Compliance isn’t optional. The Health and Safety at Work Act 1974, the Energy Performance of Buildings Regulations, and the Fire Safety Order 2005 aren’t suggestions. They’re enforceable laws. Non-compliance can lead to fines up to £20,000 per breach, or even jail time for directors in extreme cases. And with the UK’s net-zero targets pushing for deeper energy cuts by 2030, buildings that ignore efficiency are becoming liabilities, not assets.

Maintenance: From Reactive Fixes to Predictive Care

Most UK facilities still operate on a ‘break it, fix it’ model. That’s expensive. A broken boiler in January doesn’t just cost £800 to repair-it costs £3,000 in lost productivity, staff complaints, and emergency call-out fees.

The smarter approach? Predictive maintenance. It’s not sci-fi. It’s sensors on HVAC units that alert you when a motor’s vibration spikes. It’s software that tracks how often lifts are used and predicts when bearings will wear out. Companies like Serco and Compass Group have cut unplanned downtime by 40% using this method.

Start small: Track every repair for 90 days. Note the equipment, the issue, and how long it took to fix. You’ll quickly see patterns. If your coffee machines break every 14 weeks, schedule a check-up at week 10. If your lighting circuits trip after heavy rain, install better drainage before the next storm season.

Compliance: The Rules You Can’t Ignore

Here’s what you must have in place right now:

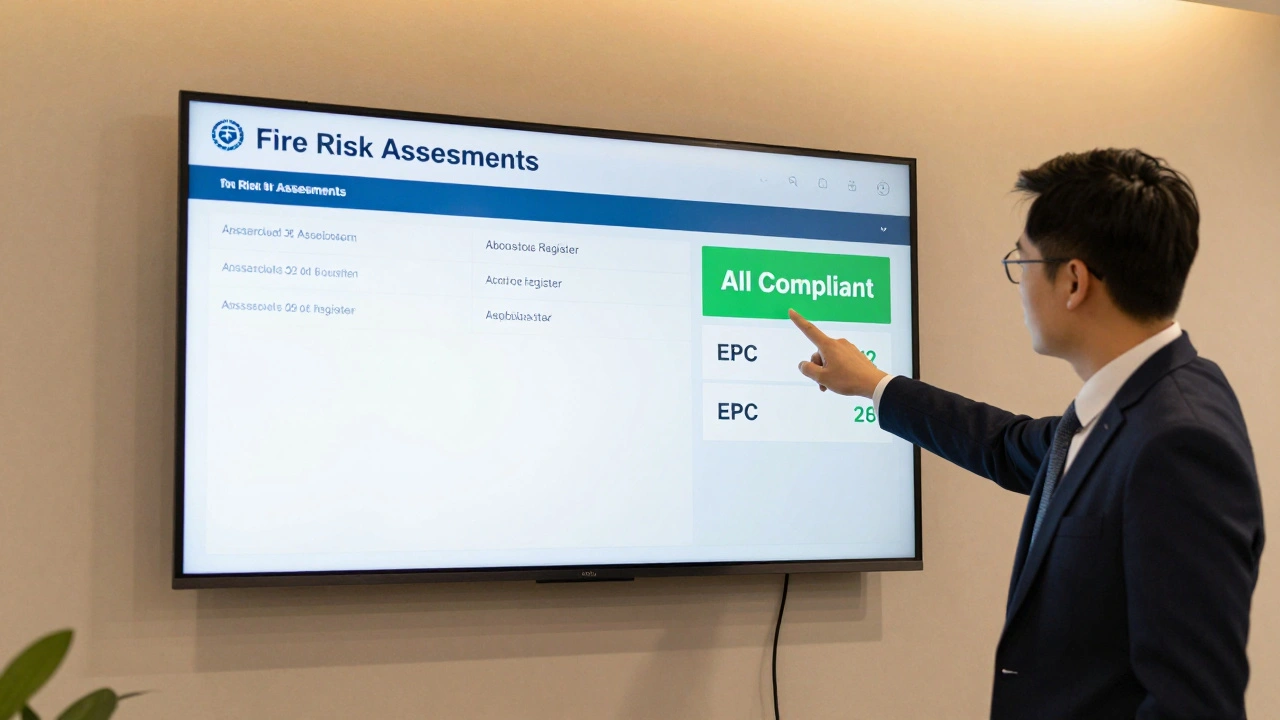

- Fire Risk Assessment: Required by law for all non-domestic buildings. Must be reviewed annually, or after any major change. If you don’t have one, you’re breaking the law.

- Asbestos Register: If your building was built before 2000, it likely contains asbestos. You must identify, label, and manage it. Ignoring this can lead to criminal prosecution.

- Electrical Safety Certificates: Every five years, fixed wiring must be tested. Landlords and employers are legally responsible.

- Legionella Control: Water systems in large buildings must be monitored to prevent bacterial growth. This includes cooling towers, hot tubs, and even decorative fountains.

- Energy Performance Certificate (EPC): You must display this for any building you rent or sell. Minimum rating is E-by 2027, it must be C for commercial properties.

Don’t rely on your cleaning crew to remind you. Use a digital compliance tracker. Tools like iAuditor or FM:Systems let you assign tasks, set reminders, and store certificates in one place. If you’re audited, you won’t be scrambling for paper files.

Cost Control: Cutting Waste Without Cutting Corners

People think cost control means hiring cheaper cleaners or skipping maintenance. That’s how you end up with a collapsed ceiling or a health inspector shutting you down.

Real cost control means spending smarter:

- Energy use: LED lighting cuts electricity bills by 60%. Smart thermostats adjust heating based on occupancy. In one NHS trust, this saved £220,000 a year.

- Outsourcing: Don’t assume in-house is cheaper. A 2024 survey found that 73% of UK SMEs saved 15-25% by outsourcing cleaning, waste, and minor repairs to specialist vendors.

- Preventive spending: Spending £500 on a roof inspection today can save £15,000 in water damage next winter.

- Contract review: Many FM contracts auto-renew with hidden price hikes. Every 12 months, compare your current vendor’s rates to the market. You’ll often find better deals.

Track your spending. Not in spreadsheets. Use a CMMS (Computerized Maintenance Management System). Even basic ones like UpKeep or Fiix cost under £50 per month and show you exactly where your money goes. You’ll stop paying for services you don’t need and catch duplicate invoices before they hit your account.

The Hidden Cost of Poor FM

Let’s say your office has a leaky roof. You ignore it. Two months later, mold grows behind the walls. Staff start complaining of headaches. HR gets a formal complaint. The building inspector flags it. You’re fined £5,000. You pay £12,000 to remediate the mold. Three employees quit. You lose another £20,000 in recruitment and training.

That’s £37,000 for a £300 repair you ignored.

That’s the real cost of bad facilities management. It’s not about the price tag on the invoice. It’s about lost time, lost trust, lost people, and lost reputation.

What Works in 2026: The New Standard

The best FM teams in the UK today aren’t just fixing things. They’re data-driven, proactive, and integrated with business goals.

They use digital twins-virtual copies of their buildings-to simulate energy use or emergency evacuations before making changes. They tie FM metrics to KPIs like employee satisfaction scores and absenteeism rates. They report directly to the CFO, not just the office manager.

If you’re still using paper checklists and Excel sheets, you’re not behind-you’re at risk.

Start with one thing: pick one building, one system (like lighting or heating), and track it for 90 days. Measure the cost of breakdowns, the time spent fixing them, and the complaints tied to them. Then fix one thing. Then another.

Small steps. Big results.

Frequently Asked Questions

Is facilities management only for large companies?

No. Even small businesses with one office need proper facilities management. A leaky pipe, a faulty fire alarm, or expired electrical certification can shut you down just as easily as in a 500-person office. The scale changes, but the risks don’t.

How often should I review my FM contracts?

At least once a year. Many contracts include automatic renewal clauses that raise prices by 3-5% annually-often without notice. Reviewing your contracts annually lets you compare market rates, negotiate better terms, or switch vendors if needed. Don’t wait until the contract expires.

Can I handle compliance myself, or do I need an expert?

You can handle basic compliance like fire risk assessments yourself if you’re trained. But for complex issues like asbestos management, legionella control, or electrical testing, you need certified professionals. DIY here isn’t cost-saving-it’s risky. A single missed asbestos sample can lead to legal action. Use experts for high-risk areas and manage the paperwork yourself.

What’s the cheapest way to start improving FM?

Start with a maintenance log. Write down every repair, no matter how small. After three months, look for patterns. Fix the top three recurring issues. That’s usually where you’ll save the most money. You don’t need fancy software-just a notebook and honesty.

How does FM affect employee productivity?

A lot. Poor lighting, uncomfortable temperatures, noisy HVAC, and broken toilets directly impact focus and morale. A 2025 study by the UK Workplace Wellbeing Centre found that employees in well-managed buildings reported 22% higher productivity and 31% fewer sick days. Good FM isn’t about cleanliness-it’s about creating a space where people can work without distraction or discomfort.

Are there government grants for improving building efficiency?

Yes. The UK government’s Public Sector Decarbonisation Scheme offers grants for public buildings to upgrade heating, insulation, and lighting. Private businesses can access the Green Business Fund in England and similar schemes in Scotland and Wales. These often cover up to 50% of the cost for energy-saving upgrades. Check the GOV.UK website for current eligibility.

Next Steps: What to Do Right Now

Don’t wait for a fire alarm to fail or a health inspector to show up. Here’s your 30-day plan:

- Day 1-5: List every building you manage. Note the year it was built and its EPC rating.

- Day 6-10: Check your compliance documents. Do you have valid fire risk assessments, asbestos registers, and electrical certificates? If not, schedule them now.

- Day 11-15: Review your last three maintenance invoices. Highlight the top three recurring repairs.

- Day 16-20: Compare your current FM vendor’s rates to three quotes from other providers.

- Day 21-30: Install a free digital tracker (like UpKeep or Google Sheets) to log every issue going forward.

You don’t need a big budget to start. You just need to start.