Process Documentation in the UK: How to Create Effective Standard Operating Procedures

8 Jan, 2026Most UK businesses don’t realize how much money and time they’re losing because their teams don’t follow the same steps. Someone leaves. Someone else takes over. Suddenly, the way things get done is guesswork. That’s not just frustrating-it’s risky. In industries like healthcare, manufacturing, or logistics, one wrong step can mean a failed inspection, a safety violation, or a lost customer. The fix? Clear, written standard operating procedures-or SOPs.

Why UK Businesses Need SOPs Now

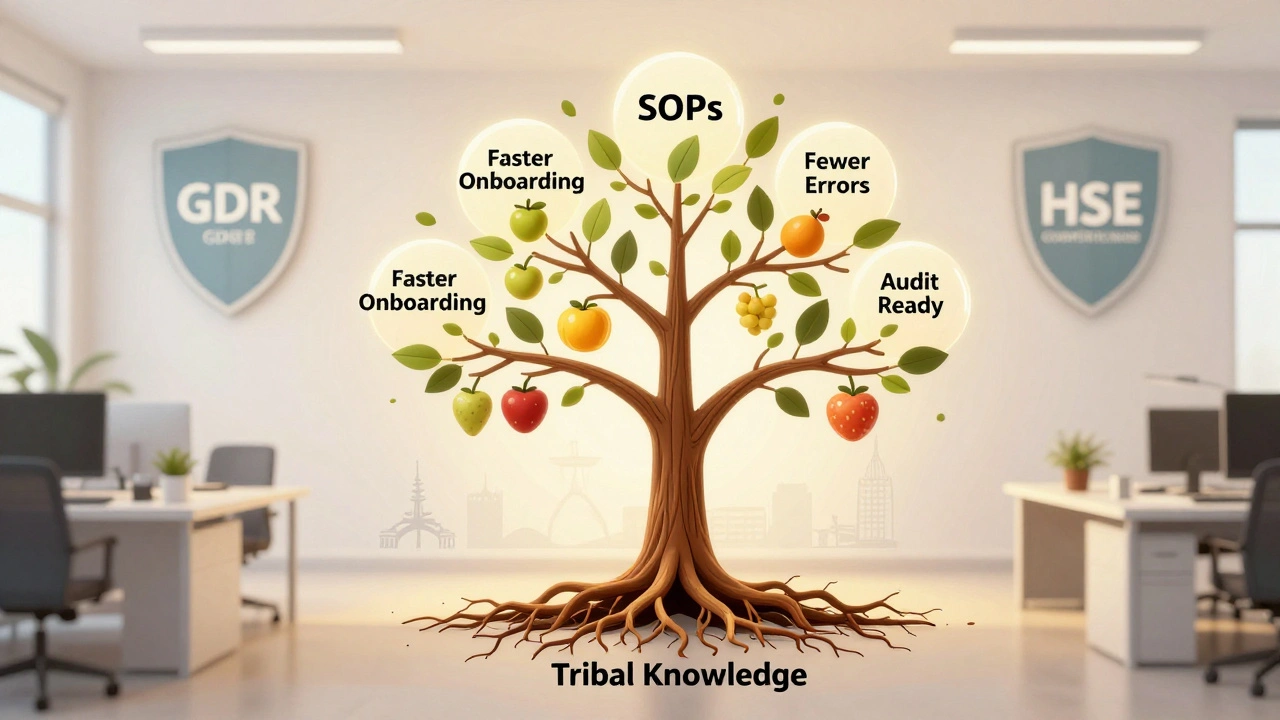

The UK’s post-Brexit regulatory landscape has made compliance more complex. From GDPR to health and safety rules under the Health and Safety Executive (HSE), businesses must prove they’re doing things the right way. Auditors don’t ask, "How do you usually do it?" They ask, "Where’s your written procedure?" A 2024 survey by the Chartered Institute of Personnel and Development (CIPD) found that UK companies with documented processes had 37% fewer operational errors and 42% faster onboarding times. That’s not theoretical. It’s happening in small manufacturing plants in Sheffield, care homes in Manchester, and logistics hubs in East London. Without SOPs, you’re relying on memory, tribal knowledge, and luck. That’s not a strategy-it’s a liability.What Makes a Good SOP?

A good SOP isn’t a 50-page manual no one reads. It’s a clear, step-by-step guide that anyone can follow-even if they’ve never done the task before. Here’s what works:- Start with the goal: "What should this process achieve?"

- Use simple language: No jargon like "leverage synergies." Say "use the customer database to update contact info."

- Break it into numbered steps: One action per step.

- Include who does it: Role or title, not just a name.

- Add visuals: Screenshots, flowcharts, or photos of equipment.

- State what to do if something goes wrong: What’s the backup plan?

- Check the delivery note against the purchase order (PO#12345).

- Verify the number of pallets matches the invoice.

- Inspect for visible damage. If damaged, take photos and email [email protected] with subject "Damaged Delivery - PO#12345".

- Scan each pallet into the WMS using the handheld scanner.

- Store in Bay C, Row 3, Shelf 2. Label with date and PO number.

Where to Start: Pick Your First Process

Don’t try to document everything at once. That’s how projects die. Start with one of these:- Processes that cause frequent mistakes

- Tasks that take longer than they should

- Jobs that new staff struggle with

- Steps that failed during a recent audit

- Any task done by someone who might leave soon

How to Write It: A Simple 5-Step Method

Here’s how to build an SOP without hiring a consultant:- Observe: Watch someone do the task. Take notes. Don’t assume you know how it’s done.

- Interview: Ask the person doing it: "What’s the trick? What usually goes wrong?"

- Write the first draft: Use plain English. No passive voice. "Click the button," not "The button should be clicked."

- Test it: Give it to someone who’s never done the task. Watch them follow it. Where do they hesitate? Where do they get stuck?

- Revise and lock: Fix the confusion points. Save it as a PDF. Put it in your shared drive with a clear name: "SOP_Inventory_Receiving_V2.pdf".

Keeping SOPs Alive

An SOP that’s not updated is worse than no SOP at all. It misleads people. Set up a simple review cycle:- Review every 6 months

- Update after any major change: new software, new equipment, new regulation

- Assign ownership: Who’s responsible for keeping this current? (Not HR. The team that uses it.)

Common Mistakes to Avoid

Most SOPs fail because of these errors:- Too long: If it takes more than 5 minutes to read, it won’t be used.

- Too vague: "Use good judgment" isn’t a step. What does "good" mean here?

- Written by managers, not doers: If the people doing the work didn’t help write it, they won’t trust it.

- Hidden away: If it’s buried in a folder called "Old Files - Do Not Use," it’s useless.

- Never reviewed: Processes change. SOPs must change too.

How SOPs Save Money

Let’s say you have a team of 10 people doing a task that takes 2 hours each time. If you can cut that time by 30 minutes using a clear SOP, you save 5 hours per week. That’s 260 hours a year. At £20/hour, that’s £5,200 saved. Now multiply that by five key processes. That’s £26,000 in labour savings alone. Add in fewer errors, less rework, faster training, and lower risk of fines-and the real savings are much higher. A 2025 report by the UK Business Federation found that SMEs with mature process documentation reduced operational costs by an average of 18% in under 12 months.

Next Steps: Your 30-Day SOP Plan

Here’s what to do in the next month:- Day 1-3: Pick one process to document. Talk to the team. Get buy-in.

- Day 4-7: Observe and interview. Write the first draft.

- Day 8-10: Test it with someone new. Record where they get stuck.

- Day 11-14: Revise and save as a PDF. Name it clearly.

- Day 15-20: Upload it to your shared drive. Tell the team.

- Day 21-30: Schedule a 10-minute check-in in two months. Will it still work?

Frequently Asked Questions

Do I need to use special software to create SOPs?

No. Free tools like Google Docs, Notion, or even Word work fine. The goal isn’t the tool-it’s the clarity. Spend your time on writing clear steps, not learning a new app. Only consider dedicated SOP software (like Process Street or ClickUp) once you have 20+ procedures and need version control or automated reminders.

How often should SOPs be reviewed?

Every six months is the standard. But update them immediately if something changes: new software, new regulations, a new team member finds a better way, or an audit points out a gap. Treat SOPs like living documents, not static files.

What if employees resist writing SOPs?

They’re not resisting the SOP-they’re resisting extra work. Frame it as helping them. Say: "This will make your job easier next time you’re sick or on vacation. Someone else can step in without you having to train them from scratch." Involve them in writing it. People support what they help create.

Are SOPs required by UK law?

Not every SOP is legally required, but many are. For example, under the Health and Safety at Work Act, employers must provide information and training on safe procedures. GDPR requires documented data handling processes. In food service, HACCP plans must be written. If you’re audited and can’t show your procedures, you could be fined or shut down.

Can SOPs make my business too rigid?

Only if you treat them like rules carved in stone. Good SOPs include a "When to deviate" section. For example: "If the scanner fails, manually enter the barcode and notify IT. Log the incident in the maintenance log." Flexibility is built in by design-so people know when and how to adapt without guessing.